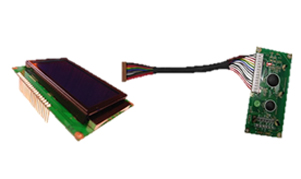

Many of our customers have found that a custom display can help to differentiate & distinguish their product against competitors. Ergonomic features can further enhance designs & interface, examples include colour coded display segments and custom graphical design. Our LCD/TFT/OLED custom design solutions are available in different options according to customer requirements. Winstar can offer various options on backlight type, pin and connector, cable, resistive touch screen (RTP) and projected capacitive (PCAP) touch screen or anti-reflective or anti-glare coating, or custom cover lens, ZIF PPC or customized PCB board or a fully custom solution for your product application, as well as System Integrated Solution

It may be that a standard display meets most of your requirements, but it’s easy to do minor modifications, such as changing the interconnect, adding a bezel or mounting frame, or modifying a backlight.

RGB backlights are a popular enhancement.

If you need a drive circuit or additional interface, that can be also be done.

Maybe you require a touchscreen? Just ask our sales team.

It’s possible to specify glass size and shape, including complex shapes such as polygons. Even convex or curved shapes are possible.

The next step is to specify the image. Character, custom icons, dot matrix or mixed mode?

You can specify interface protocol, preferred IC and interconnect options.

Chip on board, chip on glass or glass only provides flexibility in mounting. We can even add a bezel or mounting frame.

LCD type (STN, FSTN, positive or negative mode) and backlight can all be specified.

NREs (Non-Recurring Engineering Charges) and MOQ can be surprisingly small.

Samples will be provided on receipt of the NRE in order to allow final customer approval

Specifying and driving a display might not be your core competence.

Winstar’s System integration team can assist with any or all of the integration requirements leaving you free for product development and marketing.

The SI team can design the power and drive system, mounting and mechanics, and even write the software / UI.

Link to Winstar Display Solutions

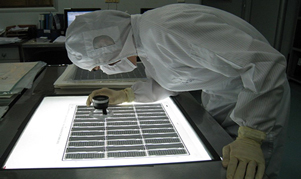

The process begins by identifying the preferred dimensions and segment content. We can advise on the most cost-effective overall size. This is generally determined by how many individual displays can be produced on one sheet of “motherglass” as it passes along the production line and can make a significant difference to unit cost. Drawings are then prepared and when approved, prototypes can be produced. Prototypes can then be evaluated and used to test the electronics design and function. Once tested and approved the custom LCD can go into mass production.

At Plus Opto our role is to advise and manage the project to ensure that the manufacturer correctly implements the design requirements. We use our expertise to reduce the time taken to arrive at cost effective and attractive display solution taking into account commercial requirements.

Whilst there is generally no MOQ imposed, the practical production order quantity is 1000pcs. Smaller quantities can be produced at higher unit costs where each project is judged on it’s own merit. All custom modules are supplied complete with drive electronics and backlights. Again these may be customised to specification. The next logical step is a turnkey display assembly.

In addition to size and segment detail, other options include:

Connector method - to suit your board layout and production processesBacklights - LED, EL and CCFL - are available.Fitted Connectors and Cable Assemblies are available.